HANDLE

THE HEAT

with your standard or custom cooling system

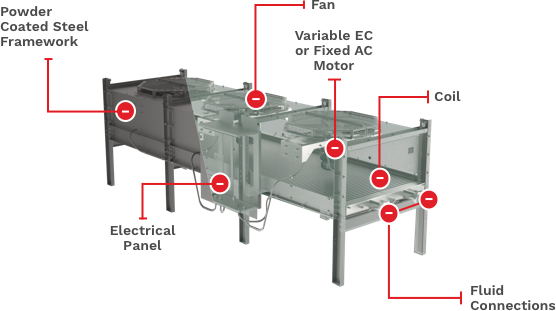

FLUID COOLER

CHILLER

Fluid Coolers and Chillers deliver cooled water or dielectric fluid to your thermoregulation equipment simply and efficiently. Get the most out of your cooling system by providing cooled fluid to Silver Linings Heat Exchangers or IT rack enclosures. Our fluid coolers & chillers are made to keep your applications at a safe & protected temperature. Learn more about our industrial liquid cooling options with our modular enclosure systems & heat exchangers.

MODULAR ENCLOSURE

HEAT EXCHANGER